When summer season temperatures upward push, so do the dangers for your forklifts and operators. Over the top warmth can result in engine overheating, battery failure, or even unsafe operating prerequisites to your crew. That’s why seasonal forklift repairs is important to fighting expensive maintenance, lowering downtime, and protective your funding. Keeping up your forklifts will have to all the time be a concern with a purpose to stay them working successfully and safely – particularly in excessive temperatures. Over the top warmth publicity can result in larger forklift engine put on and failure of portions, which in flip creates dear replacements. We have now a couple of preventative measures for summer season forklift care so as to add for your morning protection tick list.

1. Check out the Battery for Warmth-Similar Problems

Whilst checking your forklift battery is most often a part of on a regular basis repairs, sizzling climate hurries up fluid evaporation in batteries, which may end up in corrosion, decreased battery existence, and kit failure. Whilst battery assessments will have to already be a part of your day by day forklift inspection, summer season calls for further consideration.

-

Test fluid ranges steadily and most sensible off with water that fits your battery’s pH necessities

-

Blank corrosion from terminals and make sure safe cable connections

-

Believe scheduling mid-season battery carrier to increase battery existence

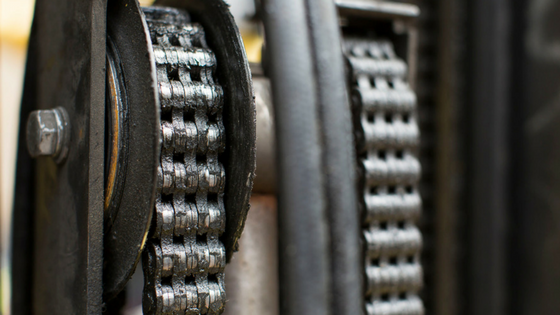

2. Read about Forklift Cables, Chains, and Connectors

Fast temperature adjustments could cause cables to change into brittle and connectors to loosen. All the way through the summer season, up to now left out injury from chillier seasons would possibly aggravate.

-

Search for cracks, fraying, or uncovered wiring in cables

-

Be sure that all connectors are safe and functioning correctly

-

Check out raise chains for put on, elongation, or indicators of rust

3. Test Engine Oil and Change When Important

Your forklift’s engine oil performs a significant position in holding portions lubricated and fighting overheating. Outdated or inadequate oil could cause larger friction, which results in engine pressure or entire failure.

-

Practice the producer’s really useful oil alternate durations

-

Use the right kind oil kind to your particular forklift type

-

Test oil ranges steadily all the way through excessive warmth

4. Deal with Your Cooling Device

The radiator is the forklift’s first defensive position in opposition to overheating. Make radiator inspections a part of your regimen all the way through the summer season months.

-

Be sure that coolant ranges are inside of the correct vary

-

Check out the radiator and hoses for cracks, leaks, or unfastened fittings

-

Use the proper form of coolant designed to your forklift type

-

Transparent away any particles from the radiator display screen to make stronger airflow

5. Check out Belts and Lovers for Put on

Your forklift’s enthusiasts and belts paintings in combination to chill the engine and flow into air. Harm to both can result in inefficient cooling and engine hassle.

When analyzing enthusiasts and belts, search for:

-

Cracks or holes

-

Indicators of over the top put on or slippage

-

Fraying or unfastened elements

-

Correct stress and alignment

Regimen inspections will will let you determine doable screw ups ahead of they change into dear issues.

6. Give protection to Your Operators from Warmth Pressure

Summer time forklift care is going past the gadget. Your operators are susceptible to heat-related sickness, particularly in unventilated or poorly cooled warehouses.

-

Supply shaded or air-conditioned spoil spaces

-

Inspire common water breaks and observe hydration

-

Set up commercial enthusiasts in high-traffic paintings zones

-

Agenda in depth duties all the way through cooler portions of the day, akin to early mornings

-

Teach personnel to acknowledge signs of warmth exhaustion or warmth stroke

Glad and wholesome operators are extra productive and no more more likely to make errors because of fatigue or overheating.

7. Further Pointers for Summer time Warehouse Protection

Along with forklift-specific repairs, stay your facility summer-ready:

-

Use reflective window movie or sunglasses to scale back indoor warmth buildup

-

Test air flow methods to verify correct airflow

-

Retailer forklift equipment and batteries in climate-controlled spaces

Protecting all the warehouse surroundings cool and secure advantages each your apparatus and your crew.

Summer time Forklift Care at The Forklift Professional

Your forklifts and your warehouse want those correct cooling procedures in position with a purpose to steer clear of useless and dear heat-related apparatus (and driving force) malfunctions. Within the sizzling warmth of summer season, keeping up your forklifts will have to all the time be a most sensible precedence to stay them working successfully and safely. Excessive temperatures can wreak havoc in your forklifts, resulting in larger engine put on and the failure of crucial portions. Those problems can briefly lead to dear replacements and downtime.

Just right information – we give all of our stock a radical inspection all the way through consumption, in addition to regimen repairs and a security test ahead of promoting! In the event you’re waiting to shop for or promote subject matter dealing with apparatus, we’re waiting to assist.